Cobot Welding System - South Coast Welding & Fabrication

South Coast Welding & Fabrication were early adopters of the cobot welding system after seeing OLP Robotics exhibiting at the Australian Manufacturing Week in 2022. Struggling with a shortage of welders, they saw an opportunity to increase capacity and quality, whilst also retaining a highly experienced welder on the verge of retirement due to a loss of hand-eye coordination. After a short training session, this employee was able to utilise the cobot to perform the tasks that he no longer could, whilst using his extensive knowledge to ensure the correct setup and quality standards. Extending the career of a motivated and willing employee is one of our favourite stories.

|

The cobot has made a huge difference with our quality of welding and speed of welding. We have been using it on a lot of small jobs that only have 10 or 20 off. One example is big window frames where the weld had to be small but consistent with a lot of metres done at once.

It has taken a little while for the boys to work out what to use it for, but once they think outside the box there are so many items. Back-up support from OLP Robotics has been great, with no issues getting back to us quickly. |

South Coast Welding & Fabrication

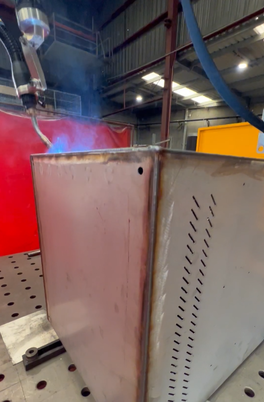

Cobot CMT Welding System - Heatlie Barbeques

|

Heatlie Barbeques specialise in manufacturing high quality stainless steel barbeques that are used across the country. Welding thin stainless steel can be a challenge, particularly when aesthetics are critical to product quality. For this application a Fronius CMT welding process was integrated with the cobot, which is an amazing technology enabling fine control over each droplet of weld material deposited, resulting in a TIG-like appearance. With this system, Heatlie were able to improve their productivity and produce consistent quality components.

|

|

Cobot Welding System - Academy Sheetmetal

Academy Sheetmetal |

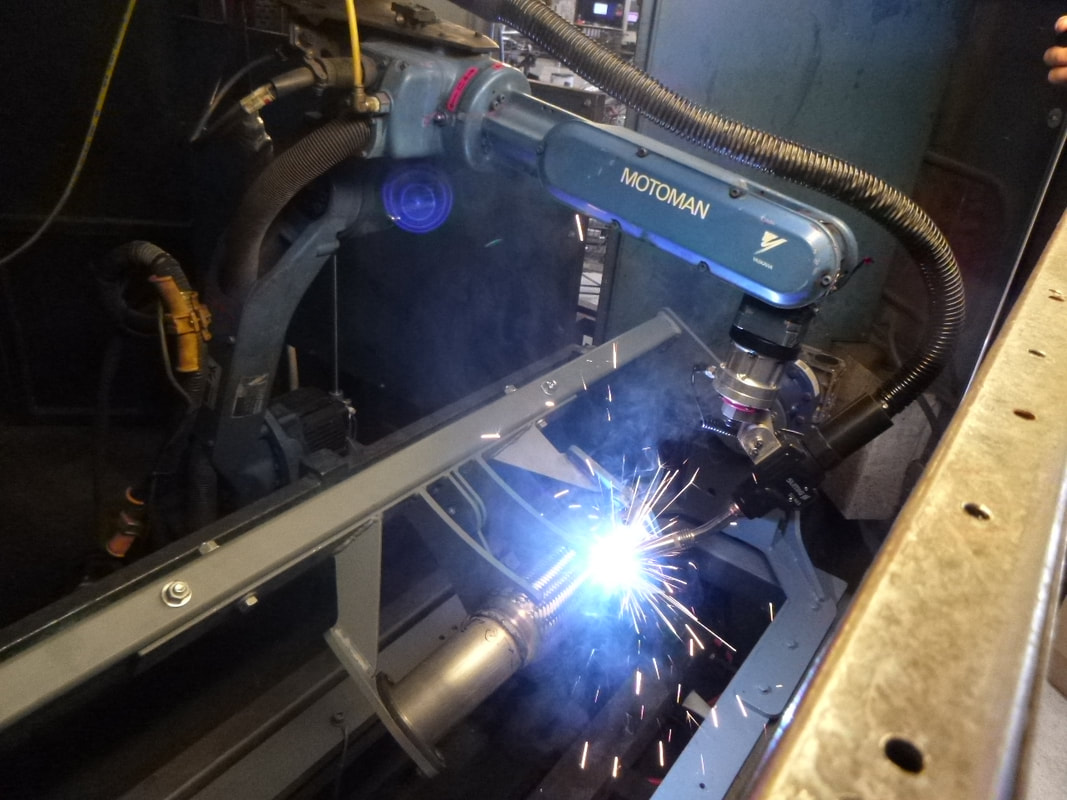

MPI Automotive Welding Cell

|

MPI Automotive purchased a used dual-station robotic welding cell and asked OLP Robotics to provide a cost-effective solution to refurbish and re-purpose it for welding of exhaust components. The cell was gutted of original electronics due to water damage and rewired with a HMI panel, allowing an easy-to-use graphical operator interface. Pneumatically operated screens and interlocks were also refurbished in order to meet safety standards. OLPR designed custom jigs for holding the unique geometry of each part in perfectly repeatable positions for welding, which were mounted on a rotator in order to enable full access to all welds. With the cell now running full-time, MPI have increased production capacity and quality across several product lines. |

Rocks Gone Welding Cell

|

Rocks Gone contacted OLP Robotics seeking assistance for programming their existing robot cell to perform tungsten chip welding on new parts. After first calibrating a virtual cell to match the real one, OLP designed new fixtures enabling accurate and repeatable part positioning. Using offline programming software and Fanuc logic, the robot was efficiently up-skilled and able to launch straight into production of new parts. Rocks Gone are now achieving higher productivity, consistent quality, and a safer operation for their staff.

|

|

Carey College STEM ExcursionAs part of an education partnership with Carey Baptist College, OLP Robotics had the pleasure and privilege of having some STEM students visit us to learn about robotics and offline programming. They had fun driving a real industrial robot, and created their own robot programs using our offline programming software which we ran on our writing robot!

OLP Robotics is dedicated to supporting education for the next generation. Please contact us if you have an interest in this area. |

|